All of our Shaft Mounted Speed Reducers (SMSR) come with galvanised torque arms and breathers. This means that they have a longer life due to complete damage protection, increasing reliability and lowering maintenance. The taper bushes are also manufactured in Stainless Steel 410 which will guarantee zero rusting, fretting, and corrosion. To further emphasise reliability, our SMSRs also feature hardened and blackened backstop bushes, steiber/ringspann sprag clutch, and keys and circlips.

Our SMSRs also have higher power to weight ratios due to a 25 degrees pressure angle and profile ground gearing. To ensure optimum performance, all gear units are fitted with high quality oil seals with heavy duty bearings on input (FAG/SKF only).

At extra cost, additional features like labyrinths, hub covers, galvanised and drilled motor mounts, extraction collars, hydraulic motor mounts, and galvanised reducing bushes are available to certify that the job gets done reliably and efficiently.

In addition, our SMSRs are interchangeable with Fenner and Sumitomo SMSRs making them very versatile.

Features

-

Gears and shaft are hardened for durability and long term usage

-

Manufactured to exceed ISO 9000 standard

-

High quality carbon and nickel alloy steel gears manufactured using test certified materials

-

Gears heat treated by gas carburisation to provide efficient hardness gradient for strength and life

-

Gears ground to din class 6 ensuring correct meshing, smooth, quiet and efficient operation

-

Every shaft and bore machined to strict tolerances and shrunk fit together providing interference fit

-

Rotating shaft and hub chemically coated to reduce corrosion thus increasing seal life

-

Cast iron casings are CNC machined to ensure correct gear and pinion centre distance

-

Ideal for conveyors and crushers

-

Torque arm kit with brackets for universal mounting included

-

Backstop assemblies for shaft mounting ensures smooth, forward operation with no back slip

-

Interchangeable with old fenner SMSR sizes; A, B, C, D, E, F, G, H and J

-

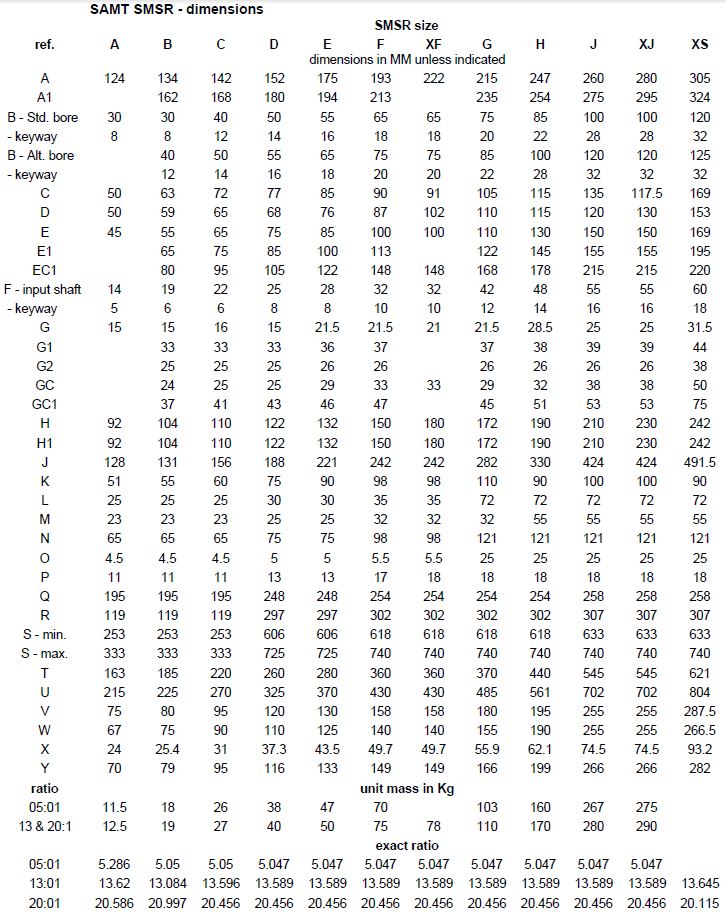

Manufactured in all different sizes from C to L with power rating of up to 150kW at 70 rpm

-

Multiple bore sizes per size & three different reduction ratios- 5:1, 13:1 and 20:1

-

Redesigned gearings for higher power to weight ratios

-

Taper clamp shaft mounted gear units - for keyless application

-

Numerous accessories: backstops, labyrinth seals, reducing bush kits, motor mounts etc.

-

Drives for hydraulic motor mounts with/without splines available on request

-

All units tested prior to dispatch with trace-ability of all components

-

Consistency & reliability in performance guaranteed in the harshest of conditions

-

Superior 25 degree pressure angle re-engineered gearing - higher power ratings

Extensive Applications

-

Feed mills

-

Stone / gravel

-

Mines

-

Rice & grain storage

-

Waste treatment & disposal

-

Cement manufacturing

-

Asphalt plants etc.